ANDRITZ develops new iron ore filter press

Published by Stephanie Roker,

Editor

Global Mining Review,

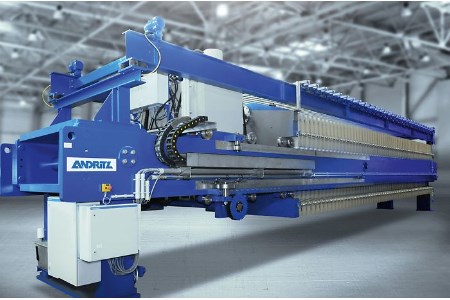

International technology group ANDRITZ has successfully started up its newly developed mining filter press for the iron ore industry at Jagannath Steel in India. This demonstrates its comprehensive know-how and capabilities in dewatering solutions for the mining and minerals industry.

The new mining filter press developed by ANDRITZ meets the specific challenges related to dewatering iron ore. Further improvements have been made in order to ensure reliable operation and maximum performance. After the iron ore has been washed out and impurities have been removed, the ANDRITZ filter press ensures maximum dewatering of the filter cake. The newly developed feed shoe design optimises and improves the machine’s performance for iron ore compared to the standard rectangular design, with measurable improvements for the client.

“With the new mining filter press, we have an additional proven and innovative product for the mining and minerals industry alongside hyperbaric filters, vacuum belt filters and the regular filter presses for iron ore concentrate dewatering. This has resulted in an optimised, reliable solution that will further boost our reputation as leading separation specialists,” concludes Robert Stantish, Managing Director of ANDRITZ Separation India.

Read the article online at: https://www.globalminingreview.com/mining/11072018/andritz-develops-new-iron-ore-filter-press/

You might also like

Technology At The Heart Of Real Progress

Max Luedtke, ABB, Switzerland, explains how connected engineering innovations such as truck electrification, gearless conveyor drives, and ventilation on demand are helping mine operators balance productivity with sustainability as they transition to the all-electric mines of the future.