Maximising Underground Efficiency

Published by Jody Dodgson,

Editorial Assistant

Global Mining Review,

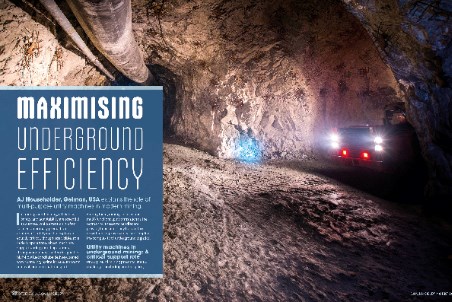

In underground mining, efficiency, safety, and adaptability are essential to success. While attention is often focused on primary production equipment, utility machines play an equally critical, though less visible, role in daily operations. These machines support underground operations through modular cassettes designed for high-flow fuel and lube delivery, zoned water spraying, hydraulic vacuum waste removal, and material transport.

Among them, mining-focused and multi-functional platforms such as the Getman A64 cassette handler are proving to be vital. They help reduce downtime, improve safety, and simplify the complexity of underground logistics.

Utility machines in underground mining: A critical support role

Underground mining presents unique challenges, including limited space, uneven terrain, and the need for uninterrupted service and maintenance of key systems. Utility machines are essential in this context. They support daily operations by delivering fuel, water, lubrication, tools, and other critical resources exactly where they are needed.

Among these, mining-focused utility machines such as the Getman A64 cassette handler stand out. Engineered specifically for the underground mining environment, they offer enhanced operator visibility, improved safety, and adaptability to a wide range of tasks. The A64 platform exemplifies this approach, providing a versatile solution that can be rapidly reconfigured to meet evolving operational needs.

The A64 cassette handler: A platform for versatility

At the core of the A64 cassette handler’s value is its modular cassette system. This system enables a single machine chassis to perform multiple roles, simply by switching out application-specific cassettes. These include configurations for fuel and lubrication service, water spraying, sump vacuuming, personnel transport, flat deck hauling, and more. The platform accommodates a payload of up to 5450 kg (12 000 lb), ensuring that it can transport significant loads without compromising safety or performance.

Each cassette is designed to be mounted and dismounted by a single operator from the safety of the cab. The process is supported by a hydraulic motor, double roller chain, shuttle hook system, and indicator lights that show the stage of cassette loading or unloading. Quick-connect hydraulic fittings are available for modules that require hydraulic flow.

This is a preview of an article that was originally published in the October 2025 issue of Global Mining Review. Subscribe to Global Mining Review for free to read this article in full and many more here.

Read the article online at: https://www.globalminingreview.com/special-reports/14112025/maximising-underground-efficiency/

You might also like

Caterpillar bolsters mining technology solutions with RPMGlobal acquisition

Caterpillar Inc. has acquired RPMGlobal, expanding its portfolio of data-driven mining technology and software solutions that help customers plan, operate, and manage their sites more efficiently.