Supporting mining’s energy transition with modular synchronous generators

Published by Jody Dodgson,

Editorial Assistant

Global Mining Review,

The energy transition presents both a challenge and an opportunity for the mining industry. From energy-intensive extraction and processing to the need for remote site electrification, the sector faces increasing pressure to reduce emissions, integrate renewable energy sources, and improve operational sustainability while still delivering the stability and reliability their operations demand.

As a result, there is a growing need for reliable generators designed to maintain the balance essential for resilience and security of supply, while also reducing energy consumption and costs. As the mining industry also works to integrate more renewable energy into its power mix, generators that can adapt quickly to changing operational demands are vital.

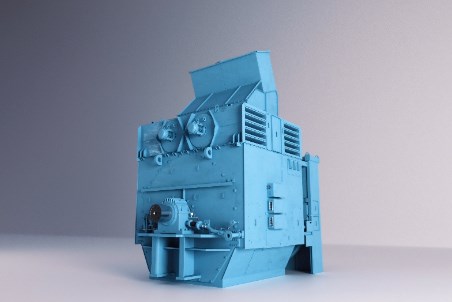

Modular synchronous generators provide a solution designed for these conditions. Their adaptable design allows operators to match power usage precisely to the operational profile of a mining site – whether continuous baseload generation for smelters and processing plants, intermediate supply for variable loads, or balancing functions to integrate renewables in hybrid systems.

One of the standout features of modern modular synchronous generators is their advanced cooling technology. With up to 60% more airflow compared to traditional systems, next-generation cooling units enable the generators to run more efficiently by reducing fan energy consumption, adapting to real-time thermal demand, and preventing overheating. For mines in remote locations where fuel and maintenance costs are high, this translates to measurable operational cost savings. Advanced cooling units can be operated on an as-needed basis, ensuring long-term performance in extreme climates and improving energy efficiency.

The ability to integrate flywheels also increases inertia to modular synchronous generators and delivers fast responses during grid disturbances. Reliability is paramount for mining operations, particularly those connected to “weak” or isolated grids, where disturbances such as voltage dips or short faults can cause process interruptions. The integration of flywheels means that modular synchronous generators can respond almost instantaneously to fluctuations and disturbances, and therefore can also adapt to country-specific grid code requirements. This capability ensures a stable supply of electricity even under challenging grid conditions, reducing the risk of costly downtime and providing confidence that critical processes will continue uninterrupted.

Additionally, the modular design of these generators supports multiple operating modes, from peak to continuous duty. Mines can configure units according to site-specific requirements such as baseload power at processing facilities, frequent start/stops at auxiliary plants, or synchronous condenser mode to stabilise renewable-heavy grids. This adaptability translates directly into improved efficiency and resilience. Mines can maintain continuous operations and optimise energy use across different duty cycles.

The modular construction is also useful for remote mines, offering compact, transport-friendly designs that can be delivered in segments and assembled on site. Built-in redundancy in advanced cooling units and robust design features mean that even if one component requires servicing, operations can continue without complete shutdowns. This resilience is vital for mines where downtime is not an option.

One important innovation of modular synchronous generators is their ability to operate as a synchronous condenser when ramped up to nominal speed by the engine and then decoupled. Synchronous condenser capabilities provide added inertia, reactive power compensation, and short-circuit capacity, which are essential for sites connected to “weak” grids. This functionality also allows operators to extract even greater value from their asset investment, optimising both CAPEX and OPEX.

As the mining industry drives forward in the energy transition, it requires solutions that combine resilience, efficiency, and adaptability. Modular synchronous generators deliver precisely that: the ability to match power supply to mining’s diverse operational needs, reduce costs through energy-efficient design, and support renewable integration while maintaining grid stability. By embracing these next-generation technologies, mining operators can ensure that their power systems are not only robust enough for today’s demands but also future-ready for the decarbonised, electrified future of the industry.

Read the article online at: https://www.globalminingreview.com/special-reports/09102025/supporting-minings-energy-transition-with-modular-synchronous-generators/

You might also like

How satellite intelligence is reshaping mining decision-making

Steve Davis, EarthDaily, explains that as mining projects grow more complex and scrutiny increases, remote sensing data and analytics are increasingly being used to manage risk across the project lifecycle .