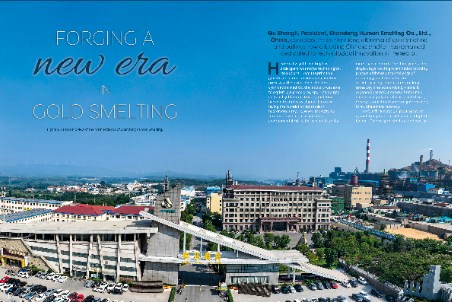

Forging A New Era In Gold Smelting

Published by Jody Dodgson,

Editorial Assistant

Global Mining Review,

Historically, gold smelting has undergone four major technological revolutions. From the primitive gravity concentration and amalgamation process to the invention of the direct cyanidation method, the industry was able to exploit low-grade ores, spurring a surge in global gold production. Cyanidation became the industry standard process, laying the foundation for modern hydrometallurgy. However, the extreme toxicity of cyanide also sowed an environmental crisis that has persisted for more than a century. The third-generation, single-stage roasting–cyanidation leaching process addressed the challenge of extracting gold from sulfur and arsenic-bearing complex ores, making refractory ores economically viable. It expanded the resource base from single gold ores to polymetallic associated ores, driving a transition from pure gold recovery to multi-element recovery.

The fourth-generation, pre-treatment–cyanidation process is still widely adopted by most Chinese gold smelters and has the advantage of low capital requirements and short metal realisation cycles. Yet, it generates enormous amounts of cyanide-laden wastewater and tailings, causing serious environmental harm. At present, more than 70% of gold in China is refined using the cyanidation process. In 2024, the country produced 534.1 t of refined gold, consuming an estimated 80 000 t of cyanide and generating over 195 million t of cyanide-bearing solid waste and 300 million m3 of cyanide-containing wastewater. Moreover, due to inherent limitations of the process, the recovery rates of valuable metals – such as gold and silver – from complex materials remain low, while associated elements cannot be effectively recovered, leading to significant resource wastage.

It is foreseeable that the continued large-scale reliance on cyanidation for gold extraction will create compounded pressures from both historical and new issues, particularly in the generation and treatment of cyanide solid waste and in ensuring safe production. The traditional cyanidation process thus faces the paradox of ‘easy extraction, difficult remediation, and low efficiency’.

This is a preview of an article that was originally published in the November/December 2025 issue of Global Mining Review. Subscribe to Global Mining Review for free to read this article in full and many more here.

Read the article online at: https://www.globalminingreview.com/mining/10122025/forging-a-new-era-in-gold-smelting/

You might also like

Hancock Prospecting media statement on licence award to Maaden Hancock JV

Midana Exploration Pty Ltd (Hancock) and Saudi Arabian Mining Company (Maaden) representatives attended a Round 9 licence award ceremony held during the Future Minerals Forum in Riyadh on 14 January 2026.